A) 2 hours

B) 2.2 hours

C) 2.33 hours

D) 2.4 hours

E) 3 hours

G) A) and C)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

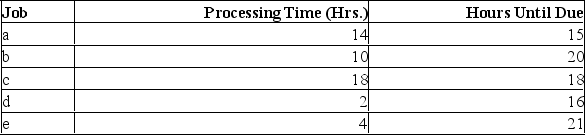

The table below contains information about five jobs waiting to be processed at work station number three.  The sequence that would result using the SPT rule is:

The sequence that would result using the SPT rule is:

A) e-b-c-d-a.

B) c-a-b-e-d.

C) a-d-c-e-b.

D) d-e-b-a-c.

E) e-d-b-a-c.

G) A) and D)

Correct Answer

verified

Correct Answer

verified

True/False

Moore's rule is a technique to minimize the number of late jobs for a group of jobs to be processed on one work centre/machine.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

The elimination of idle time on both bottleneck and non-bottleneck operations is equally important.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

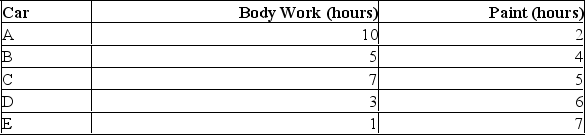

The operations manager of a body and paint shop has five cars to schedule for repair.He would like to minimize the make-span to complete all work on these cars.Each car requires body work prior to painting.The estimates of the times required to do the work at each of the two stations are as follows:  Using Johnson's rule where in the optimum sequence should car E be scheduled?

Using Johnson's rule where in the optimum sequence should car E be scheduled?

A) First

B) Second

C) Third

D) Fourth

E) Fifth

G) B) and C)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

For the jobs listed below,which processing sequence would result using Johnson's Rule? Processing time (hrs.) 11eab92b_c479_cbf3_99e6_89f1b7be27d5

A) c-a-d-b

B) b-d-a-c

C) a-b-c-d

D) d-c-b-a

E) c-a-b-d

G) B) and D)

Correct Answer

verified

Correct Answer

verified

True/False

For the Theory of Constraints,the transfer batch denotes a portion of the production lot that could be moved to the bottleneck operation.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

Forward scheduling is based on completing jobs exactly on their due date.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Monitoring and managing the work flow at each work centre on the shop-floor of a production facility is called:

A) lot sizing.

B) inventory turnover.

C) daily dispatch lists.

D) Gantt chart.

E) Input/output (I/O) control.

G) C) and D)

Correct Answer

verified

Correct Answer

verified

True/False

A major reason for scheduling difficulty is variability in setup times,processing times,interruptions,and changes in the set of jobs.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

In the drum-buffer-rope conceptualization used in the theory of constraints,the "drum" that sets the pace for production refers to:

A) work-in-process inventory before the bottleneck.

B) the bottleneck of the process.

C) total capacity of the process.

D) first stage in the process.

E) the master schedule.

G) All of the above

Correct Answer

verified

Correct Answer

verified

Multiple Choice

In scheduling staff for services,flexible capacity is achieved by:

A) part time workers and the timing of shifts.

B) using Johnson's rule.

C) offering incentives for customers to come during non-peak hours.

D) maintaining inventory.

E) managing waiting lines so customers perceptions of waiting are altered.

G) A) and C)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

When sequencing jobs with sequence-dependent setup times the goal is to:

A) Minimize total setup time

B) Maximize total setup time

C) Average the setup times

D) Minimize flow time

E) Maximize utilization

G) All of the above

Correct Answer

verified

Correct Answer

verified

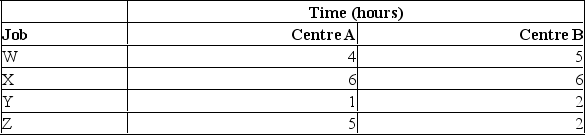

Short Answer

Given the following data for jobs awaiting processing at a manufacturing cell in which jobs are first processed by machine A,then by Machine B:

In developing the sequence which will minimize make-span,what is the second job to be added to the sequence?

In developing the sequence which will minimize make-span,what is the second job to be added to the sequence?

Correct Answer

verified

Correct Answer

verified

True/False

For services,the process of assigning work shifts to staff begins with forecasting the amount of work to be done during each hour (or shift)during the time period the schedule is being planned.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

The total time needed to complete a group of jobs from the beginning of the first job to the completion of the last job is called the:

A) job flow time.

B) make-span.

C) earliest due date (EDD) .

D) delivery time.

E) average WIP.

G) A) and E)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

A schedule/control Gantt chart is a visual representation of progress on the shop-floor which shows _______ on a vertical axis,and _______ on the horizontal axis.

A) jobs in progress; time

B) jobs in progress; total costs

C) hours worked; jobs in progress

D) total costs; jobs in progress

E) actual output; actual input

G) C) and D)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Scheduling that starts with the present time and continues into the future is called:

A) detailed scheduling.

B) staff scheduling.

C) master production scheduling.

D) forward scheduling.

E) backward scheduling.

G) A) and D)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Two different approaches to load work centres in job scheduling are:

A) economic order quantity (EOQ) and material requirements planning (MRP) .

B) Gantt charts and shop-floor control.

C) infinite loading and finite loading.

D) linear programming and trial-and-error.

E) linear programming and Gantt charts.

G) C) and D)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

The purpose of a Gantt chart is to:

A) visually express the capacity of resources.

B) quantitatively analyze the optimum sequencing of resources.

C) visually represent the loading and scheduling of jobs for control purposes.

D) quantitatively analyze the capacity of production resources.

E) visually express the material allocation at work centres.

G) A) and C)

Correct Answer

verified

Correct Answer

verified

Showing 21 - 40 of 116

Related Exams